How Long Do Mechanical Seals Last? A Comprehensive Guide

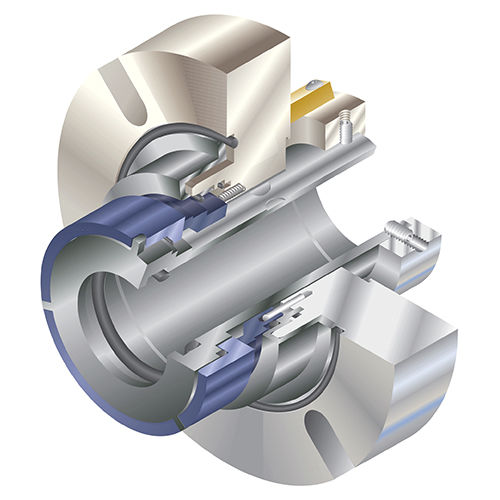

Mechanical seals are critical components in many industrial applications, including pumps, compressors, and mixers. They are designed to prevent leakage of fluids and gases and to maintain the integrity of the system. However, like any other mechanical component, they have a limited lifespan and will eventually fail. In this article, we will explore the factors that affect the lifespan of mechanical seals and provide tips on how to extend their service life.

Factors Affecting the Lifespan of Mechanical Seals

- Operating Conditions: The operating conditions of the system, such as temperature, pressure, and fluid properties, can significantly affect the lifespan of mechanical seals. High temperatures and pressures can cause the seal faces to wear out quickly, while corrosive fluids can damage the seal materials.

- Seal Design: The design of the mechanical seal can also impact its lifespan. A well-designed seal with high-quality materials and proper installation can last longer than a poorly designed seal.

- Maintenance: Regular maintenance and inspection of the mechanical seal can help identify any issues early on and prevent premature failure. Proper lubrication and cleaning can also extend the seal's lifespan.

- Operating Environment: The operating environment, such as humidity, dust, and vibration, can also affect the lifespan of mechanical seals. Harsh environments can cause the seal faces to wear out quickly, while excessive vibration can cause the seal to fail prematurely.

How Long Do Mechanical Seals Last?

The lifespan of mechanical seals can vary widely depending on the factors mentioned above. Generally, a well-designed and properly installed mechanical seal can last between 1 to 5 years. However, in some cases, they can last up to 10 years or more.

Tips to Extend the Lifespan of Mechanical Seals

- Choose the Right Seal: Selecting the right mechanical seal for the application is critical. Consider the operating conditions, fluid properties, and seal design when selecting a seal.

- Proper Installation: Proper installation of the mechanical seal is crucial to its lifespan. Ensure that the seal is installed correctly and that all components are aligned and tightened to the manufacturer's specifications.

- Regular Maintenance: Regular maintenance and inspection of the mechanical seal can help identify any issues early on and prevent premature failure. Proper lubrication and cleaning can also extend the seal's lifespan.

- Operating Environment: Ensure that the operating environment is suitable for the mechanical seal. Minimize exposure to harsh environments and excessive vibration.

Conclusion

Mechanical seals are critical components in many industrial applications, and their lifespan can significantly impact the system's performance and maintenance costs. Understanding the factors that affect the lifespan of mechanical seals and implementing proper maintenance and installation practices can help extend their service life. By following the tips outlined in this article, you can ensure that your mechanical seals last as long as possible, reducing downtime and maintenance costs.