How YE3 Series Three-Phase Asynchronous Motors Improve Energy Efficiency in Industry

Energy efficiency has become a defining factor in modern industrial decision-making. Rising electricity costs, stricter environmental regulations, and long-term sustainability goals are pushing manufacturers, utilities, and infrastructure operators to rethink the motors that drive their core equipment. In this context, YE3 series three-phase asynchronous motors have emerged as a practical and reliable solution for improving industrial energy efficiency without sacrificing performance or durability.

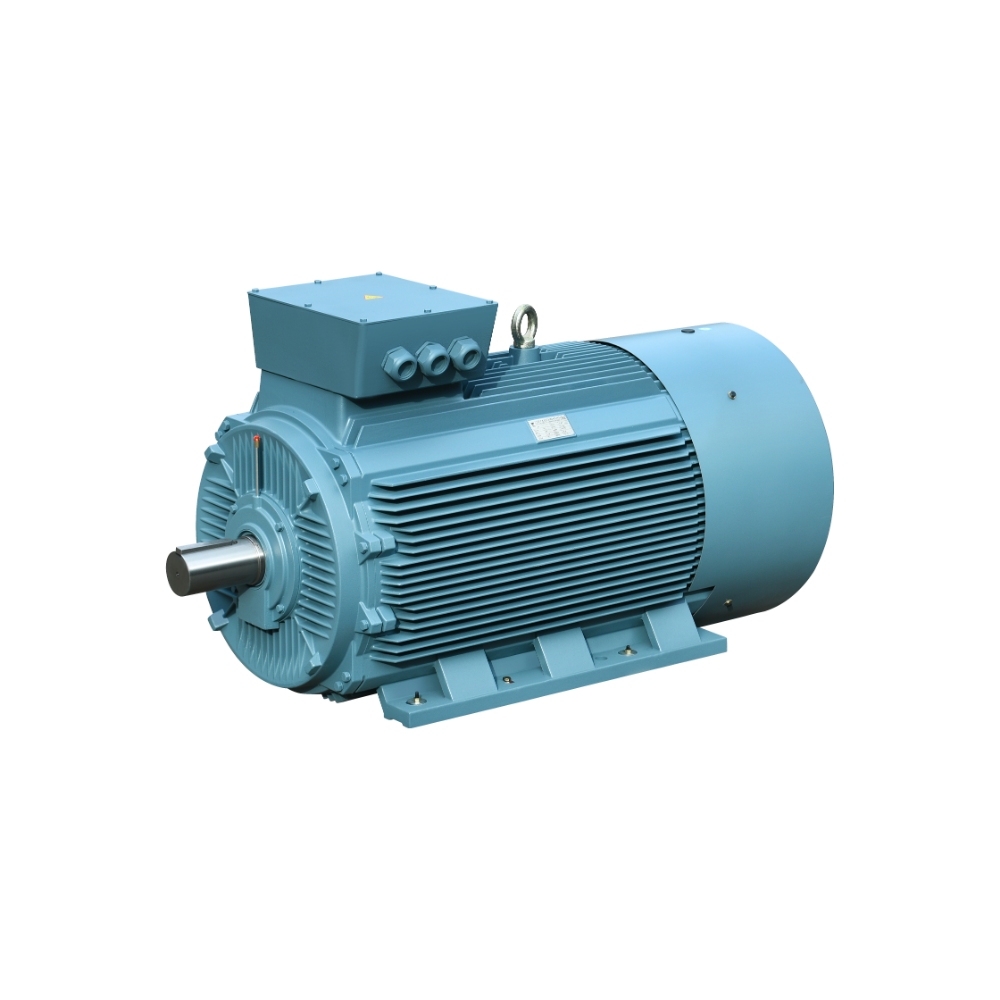

Developed independently by Zhejiang Aolong Motor Technology Co., Ltd., the YE3 series represents a new generation of high-efficiency, energy-saving motors designed specifically for real-world industrial conditions. This article explains how YE3 motors improve energy efficiency in industry and why they are increasingly chosen to replace older motor series.

The Role of Motors in Industrial Energy Consumption

Electric motors account for a significant share of total electricity usage in industrial environments. Pumps, fans, compressors, and conveyor systems often run for long hours, sometimes continuously. Even small improvements in motor efficiency can result in substantial energy savings over time.

Traditional low-voltage three-phase asynchronous motors, while robust, were not optimized to meet today’s energy efficiency requirements. As a result, upgrading to a higher-efficiency motor like the YE3 series is one of the most direct and effective ways to reduce overall energy consumption in industrial systems.

High-Efficiency Design Based on Modern Standards

The foundation of the YE3 series’ energy-saving capability lies in its compliance with both national and international efficiency standards. YE3 motors meet the Level 3 energy efficiency requirements of GB18613-2020 and are consistent with the IE3 efficiency class defined in IEC 60034-30.

In practical terms, this means that YE3 motors are engineered to minimize electrical and mechanical losses during operation. Optimized electromagnetic design, improved stator winding structures, and refined rotor configurations all contribute to higher conversion efficiency from electrical input to mechanical output.

Compared with older motor series, YE3 motors deliver the same output power while consuming less electricity, making them a direct contributor to reduced energy costs across industrial operations.

Reduced Losses and Better Thermal Performance

Energy efficiency is not only about electrical design; thermal performance plays an equally important role. Excess heat is a form of wasted energy and a major factor in motor aging.

YE3 series three-phase asynchronous motors are designed with a substantial temperature rise margin. Improved cooling structures and reduced internal losses help keep operating temperatures lower, even under continuous load or variable working conditions. Lower temperatures reduce insulation stress and slow down component degradation, which in turn maintains high efficiency throughout the motor’s service life.

In contrast, motors operating closer to their thermal limits often experience efficiency decline over time, leading to higher energy consumption and increased maintenance needs.

Stable Operation Under Real Industrial Loads

Industrial equipment rarely operates under ideal laboratory conditions. Load fluctuations, frequent starts, and harsh environments are common challenges. YE3 motors are built to handle these realities while maintaining efficient operation.

Key performance characteristics include low vibration, excellent starting performance, and stable torque output. These features ensure that the motor does not draw excessive current during startup or under partial load, both of which can significantly impact energy usage.

For applications such as pumps and fans, where motors often operate at varying loads, this stable performance directly translates into more efficient energy use across the entire operating cycle.

Long Service Life as an Energy Efficiency Advantage

Energy efficiency should be evaluated over the full lifecycle of a motor, not just its initial performance. Frequent motor replacements or repairs consume additional resources, increase downtime, and indirectly add to energy waste.

YE3 motors are designed for long service life, supported by robust construction, reliable insulation systems, and high manufacturing standards. By maintaining consistent performance over extended periods, YE3 motors avoid the gradual efficiency losses commonly seen in aging or overstressed equipment.

For industrial users, this means fewer replacements, lower maintenance frequency, and sustained energy savings year after year.

Direct Replacement for Older Motor Series

One of the practical advantages of YE3 motors is their ability to serve as full replacements for Y, YGM, YGM2, and YE2 series low-voltage three-phase asynchronous motors. In many cases, YE3 motors can be installed without significant changes to existing equipment layouts or coupling systems.

This makes upgrading to a more energy-efficient motor straightforward and cost-effective from an engineering perspective. Instead of redesigning entire systems, operators can achieve immediate energy efficiency improvements simply by replacing older motors with YE3 models.

Wide Range of Industrial Applications

YE3 series motors are designed to meet the needs of a broad range of industries. They are widely used to drive pumps, fans, compressors, and conveyor systems, all of which are major contributors to industrial energy consumption.

Their high efficiency and reliability make them particularly suitable for energy conservation projects, environmental protection initiatives, and national water conservancy programs. In these applications, long operating hours and high reliability requirements make energy-efficient motor performance especially critical.

For users seeking proven industrial motor solutions, Zhejiang Aolong Motor Technology Co., Ltd. offers a comprehensive range of YE3 and related products. More details can be found through the product portfolio at

https://www.alonmax.com/YE3-Electric-Motors

Supporting Sustainable Industrial Development

Improving energy efficiency is not only about reducing operating costs; it is also a key component of sustainable industrial development. By lowering electricity consumption, YE3 motors help reduce overall carbon emissions associated with industrial production.

For companies operating under increasingly strict environmental regulations, adopting high-efficiency motors like the YE3 series supports compliance while demonstrating a commitment to responsible energy use.

Why YE3 Motors Make Sense for Industry

YE3 series three-phase asynchronous motors combine high efficiency, strong performance, and long-term reliability in a design that reflects real industrial needs. Their compliance with modern efficiency standards, reduced losses, and extended service life make them a practical choice for industries seeking measurable energy savings.

Rather than being a theoretical upgrade, YE3 motors deliver tangible improvements in daily operation. For industrial users focused on efficiency, reliability, and future-ready equipment, YE3 motors represent a clear step forward.

About Zhejiang Aolong Motor Technology Co., Ltd.

Zhejiang Aolong Motor Technology Co., Ltd. is dedicated to the development and manufacturing of high-performance motor solutions for industrial applications. With a focus on energy efficiency, reliability, and compliance with international standards, the company provides motors designed to meet the evolving demands of modern industry.

www.alonmax.com

Zhejiang Aolong Motor Technology Co., Ltd.