MT Portable Machine Successfully Completes On-Site Repair of 2-Meter Flange for Major Petrochemical Client

MT Portable Machine has once again demonstrated its leadership in portable on-site machining solutions by completing a complex flange repair project for a major local petrochemical company. This case highlights the exceptional performance of MT’s flange facing machine during large-diameter flange restoration, particularly when traditional machining methods are not feasible.

Project Background

The customer, a well-known petrochemical enterprise, operates multiple large storage tanks used in high-pressure and corrosion-sensitive environments. One of the tanks required urgent repair due to severe damage on its 2-meter flange sealing surface. As the flange was welded directly onto the vessel shell, transporting the entire tank to a conventional machining center was impossible. This made on-site machining the only viable option.

Challenges of Large-Diameter On-Site Machining

Repairing a 2-meter flange attached to a fixed pressure vessel presents several engineering challenges:

Restricted accessibility due to tank size and surrounding pipework.

High precision requirements to restore the sealing surface to ASME and API specifications.

Vibration control and structural stability during cutting operations on thin-wall tank structures.

Tight shutdown schedule, requiring rapid deployment and efficient machining cycles.

Traditional repair methods could not meet these requirements, making portable flange machining essential.

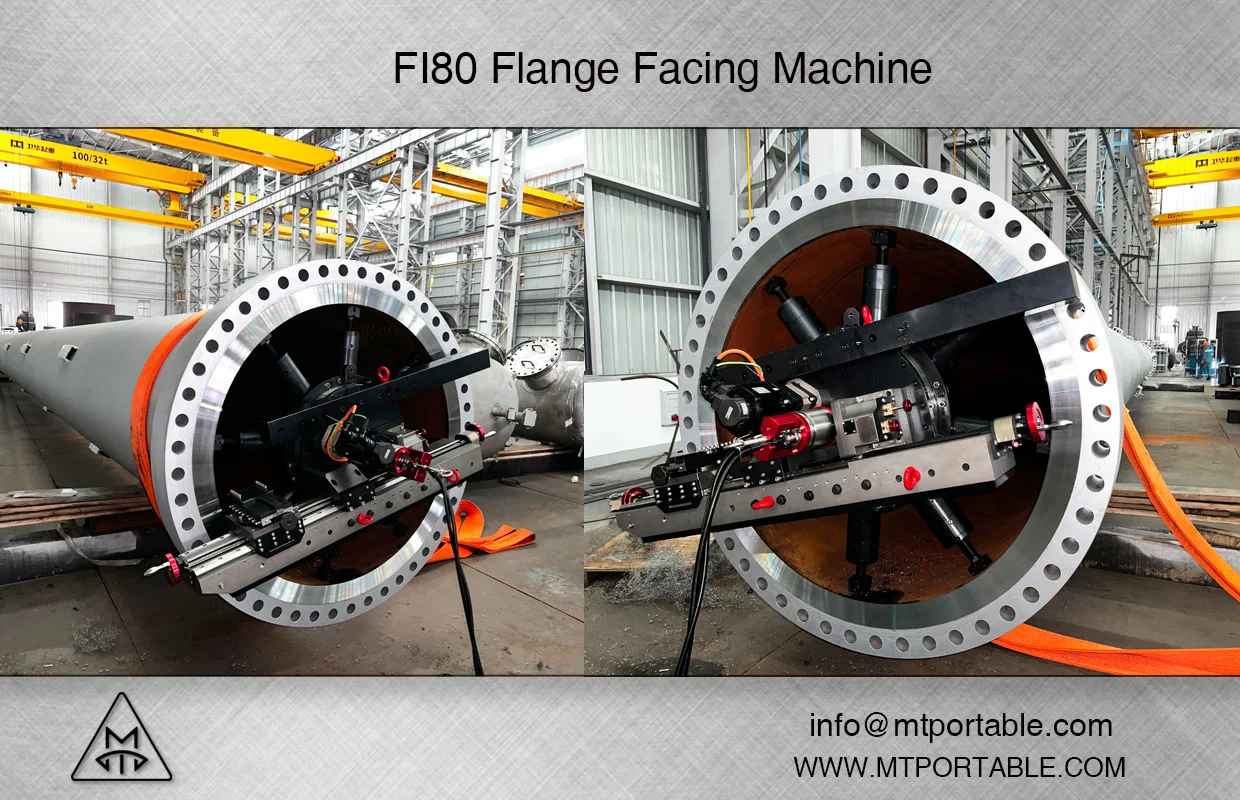

MT’s Solution: High-Performance Flange Facing Machine

MT Portable Machine deployed its heavy-duty flange facing machine, engineered specifically for large-diameter and high-accuracy flange resurfacing. The equipment’s rigid structure, adjustable feed system, and powerful drive assembly allowed stable machining across the full 2-meter diameter.

With decades of field expertise, MT’s on-site repair team quickly evaluated the flange condition, determined the optimal cutting parameters, and restored the sealing surface to a precise spiral-groove finish suitable for high-pressure gasket sealing.

Why MT Portable Machine?

This successful project was the fourth time the petrochemical company selected MT Portable Machine for critical on-site repairs. The reasons include:

Experienced field service team capable of handling complex, large-scale machining tasks.

Rapid response capability, minimizing shutdown time and operational losses.

Advanced portable machining equipment that ensures precision, stability, and reliability.

Proven performance in global pressure vessel, storage tank, and refinery maintenance applications.

MT once again demonstrated that it is not only a manufacturer of portable machining tools but also a trusted engineering service provider capable of solving the most challenging on-site machining problems.

Conclusion

The successful restoration of the 2-meter flange sealing surface reinforces the value of MT Portable Machine’s equipment and field service expertise for the petrochemical industry. For any on-site machining challenges—including flange facing, milling, line boring, or complex repair scenarios—customers are encouraged to contact MT’s technical team for professional support, updated product specifications, and tailored repair solutions.

www.mtportable.com

Jichuang Machinery Manufacturing Wuxi Co.,Ltd