Optimizing Your Production Line with Water Filling Machines

Improving production efficiency has become a central goal for beverage manufacturers worldwide. Whether you produce bottled water, juices, carbonated drinks, or large-volume gallon containers, the ability to maintain consistent quality while reducing downtime is critical for long-term business growth. Modern water filling machines play an increasingly important role in achieving this balance, helping companies streamline operations, enhance product safety, and strengthen competitiveness in global markets.

In recent years, the rapid advancement of automation, digitalization, and smart manufacturing has pushed beverage producers to rethink the design of their production lines. This shift is especially visible in the growing demand for high-efficiency filling systems that integrate multiple processes into a single, compact, and intelligently controlled unit. These machines are no longer simple mechanical equipment; they are the backbone of a factory’s operational ecosystem.

Among the innovators in this field, Pengxiang Huixing has earned recognition for its holistic approach to beverage production equipment. The company’s range of solutions covers water treatment, beverage pretreatment systems, PET blowing equipment, blow-fill production lines, labeling systems, conveying systems, and secondary packaging equipment. With a strong focus on smart workshops and smart factories, the company offers high-end planning, design, and R&D for liquid beverage packaging technologies. For manufacturers seeking to optimize efficiency, reliability, and long-term performance, understanding how modern water filling machines fit into the bigger operational picture is essential.

Why Water Filling Machines Matter

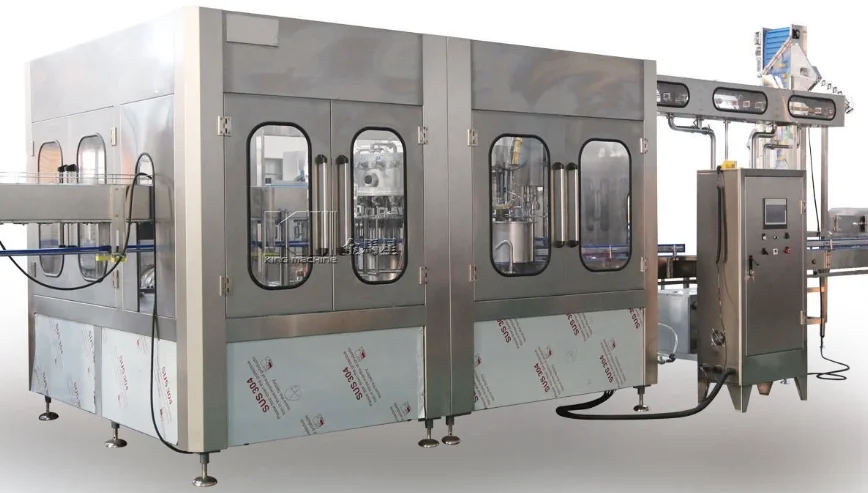

Water filling machines are central to any bottled water production line. They influence product quality, hygienic standards, production speed, and overall cost efficiency. A modern system integrates rinsing, filling, and capping within a single machine. This reduces manual handling, lowers contamination risks, and ensures product consistency.

These machines can also be adapted for different bottle types, ranging from small PET bottles to large gallon containers. As customer demand shifts toward variety, flexibility becomes a major advantage. High-efficiency filling solutions allow manufacturers to change bottle sizes or switch between product types with minimal downtime.

For readers exploring the technical specifications or applications of water filling systems, a useful reference page is embedded below:

<a href="https://www.szpxhx.com/water-filling-machines.html" target="_blank">water filling machines</a>

This page provides an overview of machine configurations and practical use cases.

Key Components of an Optimized Production Line

An optimized beverage production line is not built around a single machine; it requires a series of coordinated systems working seamlessly. Pengxiang Huixing provides integrated solutions that cover every stage of the production lifecycle.

1. Water Treatment Systems

Clean water is the foundation of quality beverage production. Advanced filtration, disinfection, and reverse osmosis technologies ensure that every bottle meets regulatory and customer expectations. Water treatment equipment must offer stable performance, easy maintenance, and efficient operation over long production cycles.

2. Beverage Pretreatment Systems

Pretreatment systems handle mixing, homogenization, blending, and sterilization for juice, tea, and flavored beverages. Consistency in these early steps ensures that the final product has the desired taste, clarity, and shelf stability.

3. PET Blowing Machines

PET bottles remain the global standard for beverage packaging due to their lightweight, durability, and recyclability. Pengxiang Huixing offers fully automatic PET blowing machines that combine energy efficiency with rapid mold changeovers. These systems support a wide range of bottle shapes and sizes, enabling manufacturers to respond to market trends quickly.

4. Blow-Fill-Seal and Blow-Label-Fill-Seal Lines

These advanced production lines merge multiple processes into one continuous operation. The result is a cleaner, more efficient workflow with less labor involvement. This is especially valuable for manufacturers handling high-volume bottled water or beverages requiring a high level of hygiene control.

5. Labeling and Conveying Systems

Accurate, smooth labeling is important for brand presentation and traceability. Conveying systems connect each stage of the production line, minimizing bottlenecks and ensuring consistent throughput. Sensors, automation software, and real-time monitoring contribute to improved efficiency.

6. Secondary Packaging Solutions

Packaging systems such as carton packers, shrink wrappers, and palletizers help manufacturers streamline shipping and storage. Optimized secondary packaging reduces product damage during transportation and improves warehouse organization.

The Role of Smart Manufacturing

As the beverage industry evolves, traditional equipment alone is no longer sufficient. Smart manufacturing solutions integrate sensors, automation controls, and data analytics into production lines. This allows operators to detect issues early, predict maintenance needs, and optimize machine performance based on real-time data.

Pengxiang Huixing has emphasized R&D in this domain, supporting complete planning and design for smart workshops and smart factories. By combining AI-assisted monitoring, energy-efficient systems, and digital production management, producers can reduce waste and increase operational visibility.

A Global Supplier with Proven Experience

Located in Songgang Street, Baoan District, Shenzhen, Pengxiang Huixing is a comprehensive beverage packaging machinery manufacturer integrating R&D and production. With ISO9000 quality management system certification and recognition as a National High-Tech Enterprise, the company has built a reputation for delivering reliable, innovative manufacturing solutions.

Over the past two decades, the company has introduced and refined advanced beverage packaging machine technologies from around the world. Guided by the philosophy of “introduction and improvement, technological progress,” it has continually optimized its product lines to meet modern production requirements.

Its equipment is widely used across more than 20 provinces in China and exported to regions including the UAE, Oman, Vietnam, the Philippines, and Malaysia. The strong market performance reflects the trust and satisfaction of global clients.

Practical Benefits for Manufacturers

When properly integrated, water filling machines and supporting equipment offer significant production advantages:

Higher Efficiency

Modern filling machines reduce downtime and support continuous operation. Combined systems—such as rinse-fill-cap units—simplify management and improve overall throughput.

Better Hygiene and Safety

Automated systems limit contact between workers and the product. This is critical for bottled water and beverages requiring sterile processing conditions.

Lower Operational Costs

Efficient energy use, reduced waste, and minimal manual intervention contribute to sustainable operations.

Scalability

Manufacturers can expand production capacity by adding modules or upgrading specific components instead of restructuring the entire factory.

Consistent Product Quality

Automated control ensures each bottle is filled to precise standards, reducing quality fluctuations.

How to Choose the Right Water Filling Machine

Selecting the right equipment depends on production goals, bottle types, beverage characteristics, and factory space. Key considerations include:

– Desired production output

– Type of beverage (still water, juice, carbonated drinks, etc.)

– Bottle materials and sizes

– Required level of automation

– Integration with existing or planned production lines

– Long-term maintenance and service availability

Working with a supplier that offers end-to-end solutions makes this process easier. Pengxiang Huixing’s extensive product catalog—from gallon barrel production lines to industrial cleaning systems—helps manufacturers build customized configurations that support their operational goals.

Final Thoughts

Optimizing your production line begins with choosing equipment that enhances efficiency and supports long-term growth. Modern water filling machines are more than simple mechanical devices—they form the core of an intelligent, well-designed beverage production ecosystem.

By incorporating advanced technologies, flexible configurations, and integrated smart manufacturing solutions, companies like Pengxiang Huixing help beverage producers meet global standards while remaining competitive in dynamic markets. Whether you are upgrading an existing line or planning a new facility, investing in high-quality filling and packaging equipment sets the foundation for future success.

www.szpxhx.com

Pengxiang Huixing