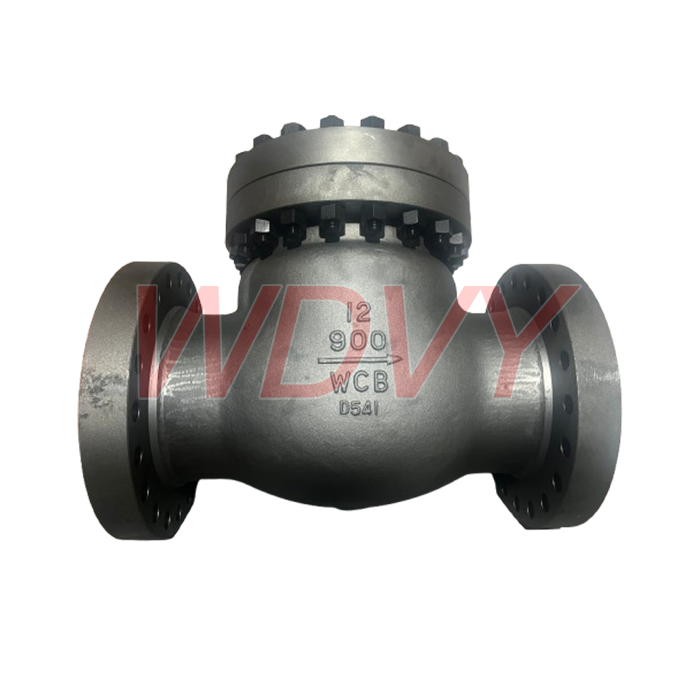

Class 900 Bolted Bonnet Swing Check Valve: Design Features and Performance in High-Pressure Systems

In high-pressure industrial systems, flow control reliability is critical for safety, efficiency, and long-term operational stability. Among the most trusted solutions for preventing reverse flow in demanding environments is the Class 900 Bolted Bonnet Swing Check Valve. Designed for high-pressure and high-temperature applications, this valve type plays a vital role in power generation, oil and gas, petrochemical processing, and other heavy-duty industries.

As a professional industrial valve manufacturer, Zhejiang Wandong Valve Co., Ltd. brings deep manufacturing expertise and vertically integrated production capabilities to the design and supply of swing check valves and a wide range of critical flow control products.

Understanding the Role of Class 900 Swing Check Valves

A swing check valve allows fluid to flow in one direction while automatically preventing backflow when system pressure drops or reverses. The Class 900 pressure rating, defined by ASME standards, indicates suitability for extremely high-pressure service, making these valves essential for:

-

High-pressure steam pipelines

-

Refinery and petrochemical units

-

Boiler feedwater systems

-

Supercritical and ultra-supercritical power plants

-

Offshore and subsea installations

The bolted bonnet construction further enhances strength, sealing integrity, and maintainability under harsh operating conditions.

Key Design Features of Class 900 Bolted Bonnet Swing Check Valves

1. Bolted Bonnet Structure for High Integrity

The bolted bonnet design provides a strong mechanical connection between the body and bonnet, ensuring excellent sealing performance under extreme pressure and temperature. This structure allows easy disassembly for inspection and maintenance without cutting the valve from the pipeline.

2. Heavy-Duty Body and Disc Construction

Class 900 swing check valves are typically manufactured from forged carbon steel, alloy steel, or special stainless steels to withstand thermal stress and corrosion. Precision-machined discs and hinge mechanisms ensure smooth movement and rapid closure when flow reverses.

3. Optimized Flow Path

The swing-type disc opens fully under forward flow, minimizing pressure drop and turbulence. This design improves system efficiency while reducing erosion and vibration in high-velocity service.

4. Advanced Sealing Technology

Metal-to-metal seats, hardfacing overlays, and precision lapping processes provide tight shutoff even after long service cycles. In high-temperature systems, this sealing performance is critical for safety and energy efficiency.

5. Compliance with International Standards

High-quality Class 900 valves are produced in accordance with standards such as ASME B16.34, API 6D, and API 594, ensuring compatibility with global engineering projects and regulatory requirements.

Performance Advantages in High-Pressure Systems

Reliable Backflow Prevention

In high-pressure pipelines, reverse flow can cause severe damage to pumps, compressors, and upstream equipment. Swing check valves provide automatic, fast response to pressure changes, protecting critical assets.

Long Service Life

Robust materials and precision manufacturing extend service intervals, reducing downtime and lifecycle costs in continuous-operation facilities.

Low Operating Resistance

The fully opening disc design minimizes pressure loss, making these valves ideal for high-capacity transmission lines and energy-intensive systems.

Stable Operation at High Temperature

From superheated steam to high-temperature hydrocarbons, Class 900 swing check valves maintain dimensional stability and sealing performance under thermal cycling.

Manufacturing Strength of Zhejiang Wandong Valve Co., Ltd.

Zhejiang Wandong Valve Co., Ltd. is a vertically integrated industrial valve manufacturer with specialized production workshops, including:

-

Ball Valve Workshop for precision spherical sealing products

-

Large-Diameter Gate Valve Workshop for pipeline and power projects

-

Special Stainless Steel Valve Workshop for corrosive and high-temperature service

-

Multi-Function Workshop producing gate valves, globe valves, check valves, Y-type strainers, and more

This comprehensive manufacturing structure enables Wandong to control quality across every stage—from raw material selection and forging to machining, assembly, and testing. The company’s swing check valves are engineered for reliability in critical high-pressure applications across power generation, chemical processing, and oil and gas industries.

Typical Applications

Class 900 bolted bonnet swing check valves are widely used in:

-

Thermal and nuclear power plants

-

High-pressure boiler feedwater systems

-

Refinery process units

-

High-pressure gas transmission pipelines

-

Offshore production platforms

Their robust design and dependable performance make them a cornerstone of modern high-pressure flow control systems.

Conclusion

The Class 900 Bolted Bonnet Swing Check Valve represents a vital component in safeguarding high-pressure industrial systems. With its heavy-duty construction, optimized flow design, and proven sealing performance, it delivers reliability where failure is not an option.

Backed by vertically integrated manufacturing and multi-specialty workshops, Zhejiang Wandong Valve Co., Ltd. continues to provide high-performance valve solutions that meet the strict demands of global energy and process industries. For engineers and project managers seeking durable, standards-compliant check valves, this design remains a trusted choice for long-term system integrity and operational safety.

www.wdfmvalves.com

Zhejiang Wandong Valve Co., Ltd.