Unveiling the Marvels of Additive Manufacturing: The Intricate World of 3D Printed Plastics

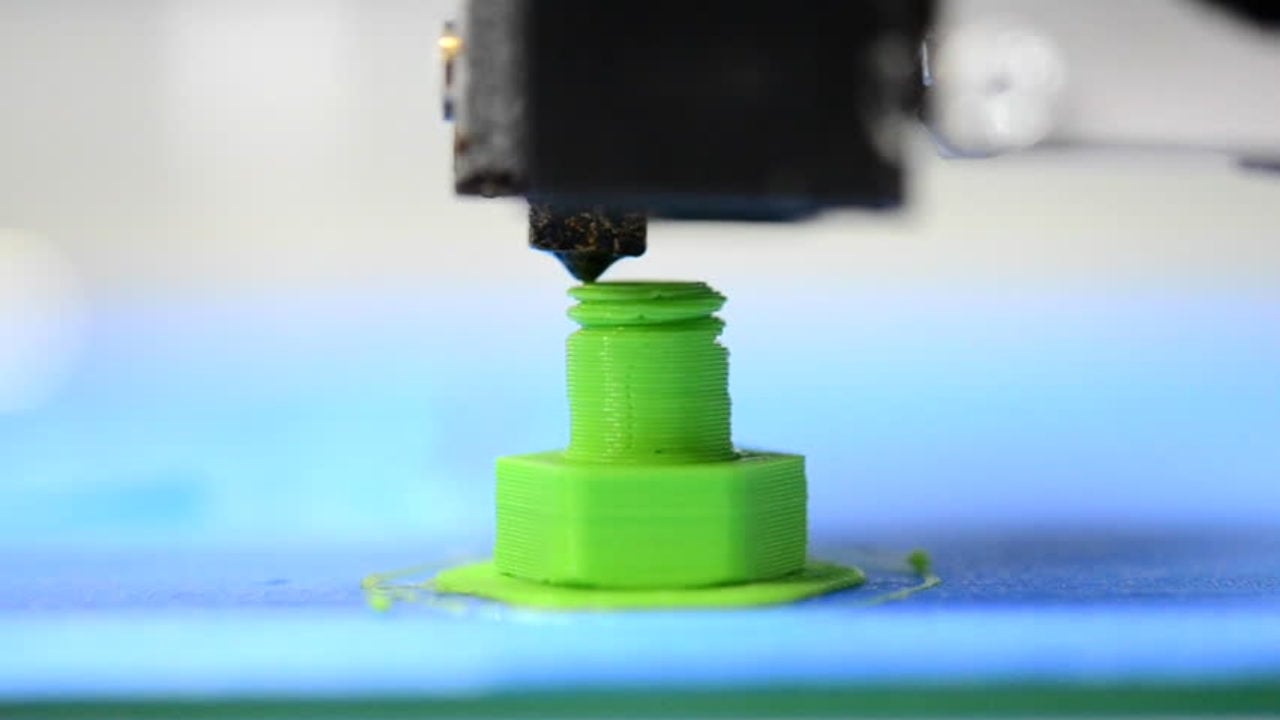

In the realm of additive manufacturing, 3D printing has revolutionized the way we create objects. With its ability to fabricate intricate designs layer by layer, this technology has found applications in various industries. One of the key materials used in 3D printing is plastic, but what exactly is it called in the context of this innovative manufacturing process? In this blog post, we will delve into the world of 3D printed plastics, exploring their types, properties, and the latest advancements in this ever-evolving field.

- Understanding the Terminology:

The term commonly used to refer to 3D printed plastic is filament. Filament is a thermoplastic material that is fed into the 3D printer, melted, and extruded layer by layer to create the desired object. It comes in various forms, such as spools or coils, and is available in different colors and materials, each with its unique characteristics. - Exploring the Types of 3D Printed Plastics:

a) Polylactic Acid (PLA): PLA is one of the most popular choices for 3D printing enthusiasts due to its ease of use, biodegradability, and low toxicity. Derived from renewable resources like cornstarch or sugarcane, PLA offers a wide range of colors and is suitable for creating prototypes, artistic models, and consumer products.

b) Acrylonitrile Butadiene Styrene (ABS): Known for its durability and impact resistance, ABS is commonly used in industrial applications. It exhibits excellent mechanical properties, making it suitable for functional prototypes, automotive parts, and electronic enclosures. However, it requires a heated print bed and proper ventilation due to the emission of potentially harmful fumes during printing.

c) Polyethylene Terephthalate Glycol (PETG): PETG strikes a balance between the ease of printing and mechanical strength. It offers high impact resistance, chemical resistance, and transparency, making it suitable for applications such as medical devices, food containers, and mechanical parts.

d) Nylon: Nylon filaments provide exceptional strength, flexibility, and heat resistance. They are widely used in engineering applications, including gears, bearings, and functional prototypes. Nylon filaments can be reinforced with carbon fiber or glass fiber to enhance their mechanical properties further.

- Advancements in 3D Printed Plastics:

The field of 3D printed plastics is constantly evolving, with researchers and manufacturers pushing the boundaries of what is possible. Here are a few notable advancements:

a) Composite Filaments: Manufacturers are developing composite filaments by combining plastics with other materials like wood, metal, or carbon fiber. These filaments offer enhanced strength, aesthetics, and unique properties, opening up new possibilities for functional and artistic creations.

b) Flexible and Elastic Filaments: Innovations in filament formulations have led to the development of flexible and elastic materials, allowing for the creation of objects with rubber-like properties. These filaments find applications in industries such as footwear, robotics, and prosthetics.

c) Biodegradable and Sustainable Filaments: With a growing focus on environmental sustainability, biodegradable filaments made from materials like algae, hemp, or recycled plastics are gaining traction. These filaments offer an eco-friendly alternative for various applications, including packaging, consumer goods, and medical devices.

Conclusion:

The world of 3D printed plastics is a captivating realm where innovation and creativity converge. From the versatile PLA to the robust ABS and beyond, the range of materials available for 3D printing continues to expand. As technology advances, we can expect even more exciting developments in the field, pushing the boundaries of what can be achieved with 3D printed plastics. So, whether you are an enthusiast, designer, or industry professional, embrace the possibilities and unlock the potential of this remarkable manufacturing process.